3 Reasons To Get Electromagnetic Rf Shielding

RF interference can interfere with everything from the cellular networks used for communication to medical devices like MRI machines. That’s why RF shielding is crucial in a wide variety of industries.

Copper is a good choice for RF shielding because it attenuates and absorbs EM waves’ magnetic and electric components. It’s also naturally corrosion-resistant and has impeccable electrical conductivity.

Reduce Interference

A wide range of electronics and devices emit electromagnetic signals that can interfere with other circuits. This can cause many problems, from minor annoyances to severe damage or death. RF shielding helps prevent these issues by creating a physical barrier between courses to absorb or reflect interference signals.

Conductive fabrics are lightweight textiles that are coated or combined with metals, such as nickel and copper. These materials can be used in various applications, including RFI shielding. They can also reduce static on phone lines and AM, FM, and TV stations.

EMI shielding is available in various shapes, sizes, and weights. Conductive aluminum is a popular choice for EMI shielding because it has an excellent strength-to-weight ratio and high electrical conductivity. It’s also durable and resistant to corrosion. It can be easily cut to fit the dimensions of a device. Other options include stainless steel and nickel silver, which have a higher permeability than copper.

Increase Product Lifespan

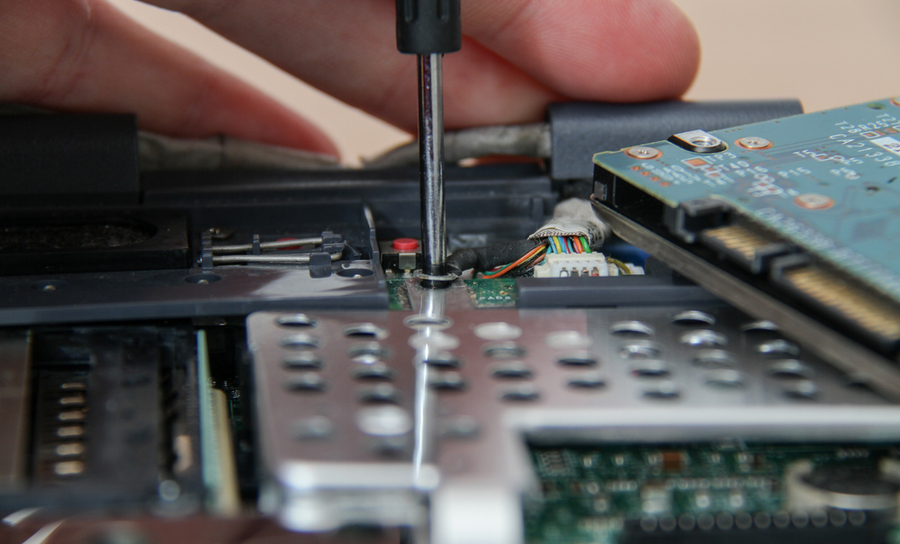

While many things can lower the performance of a printed circuit board and ultimately cause it to fail, radiofrequency electromagnetic radiation tends to top the list. RF shielding can limit the effects of this interference and help your electronic devices last longer.

Several materials can be used to make RF shielding. Copper is one of the most versatile materials because it can block radio waves and magnetic interference. It is also highly conductive and has high permeability. Copper can be combined with other metals to create alloys like brass for various applications. It is also relatively inexpensive and easy to shape into desired forms.

Aluminum is another common material for RF shielding. It blocks frequencies up to the lower GHz range and has an excellent strength-to-weight ratio. It can be fabricated easily and has good corrosion resistance. It can also be plated with tin to improve corrosion resistance and solder ability.

Reduce Costs

There are a variety of EMI shield materials that effectively block electromagnetic interference. The best choice depends on your design, manufacturing process, and tolerances. A precision stamper can help you optimize your RF shield design for manufacturability so it is efficient and meets specifications for flatness, profile tolerance, corner angles, and technical cleanliness.

Medical equipment and facilities must comply with stringent EMI/RFI protection to avoid glitches that could cause harm to patients or staff. The same goes for military systems, banking and business, R&D labs, and other electronic devices.

Metals are the most traditional and preferred RF shield material for their effectiveness in blocking electromagnetic interference. Copper, for example, is highly effective at absorbing the magnetic and electrical components of EMI waves. Moreover, it is durable, cheap to produce, and corrosion-resistant. Additionally, copper alloy 770 is easy to form and install in different types of electronics. Another option is Mu-metal, which combines nickel and iron for better protection against electromagnetic interference.

Increase Efficiency

RF shielding prevents electromagnetic interference (EMI) signals from contaminating and distorting medical device signals to reduce the risk of equipment malfunction, resulting in improved patient safety and decreased healthcare costs. RF shielding is also used in magnetic resonance imaging (MRI) scanners to protect patients from electrical, magnetic, and radiofrequency signal interference.

The primary purpose of RF shielding is to prevent interference from radiofrequency electromagnetic impulses. These waves can interfere with the electric circuitry of a PCB and alter how it usually functions. This can lead to power failures and other issues that may threaten the overall functioning of an electronic device.

Some of the most common RF shielding materials include aluminum, copper, and conductive fabrics. The conductive fabric utilizes a substrate like nylon or polyester combined with metal or nothing but metallic particles. It drapes well, is easy to work with, and offers moderate protection. However, if flexed or stretched too much, it might lose its effectiveness.